Centroglide

The special POM with excellent sliding characteristics

The special POM with excellent sliding characteristics

Find materials, compare, enquire:

Find the plastic of your choice with just a few clicks!

Professional material development is one of the particular skills of the Centroplast development team. One of our innovations is POM Centroglide, which has a special material formulation:It combines good wear and abrasion characteristics with very low sticking and adhesive effect.

The combination of these two contradictory properties provides significant economical advantages and product quality benefits for the user due to the longer replacement intervals and longer service life.

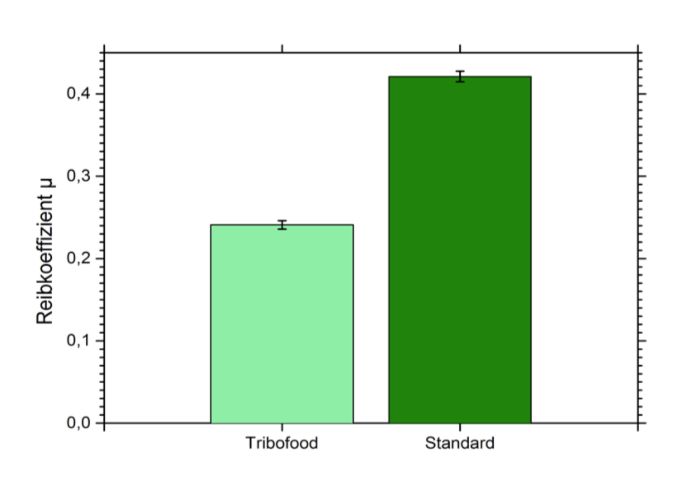

The following diagram shows the friction value of Centrodal (POM Copo, Standard with food-grade certification) in comparison to the new development POM CentroGlide, likewise with food-grade certification: The CentroGlide is easy to identify with its friction value almost half that of Centrodal. This is indicative of excellent sliding characteristics.

Comparison of the average friction value of Centroglide (left) and Centrodal (right)

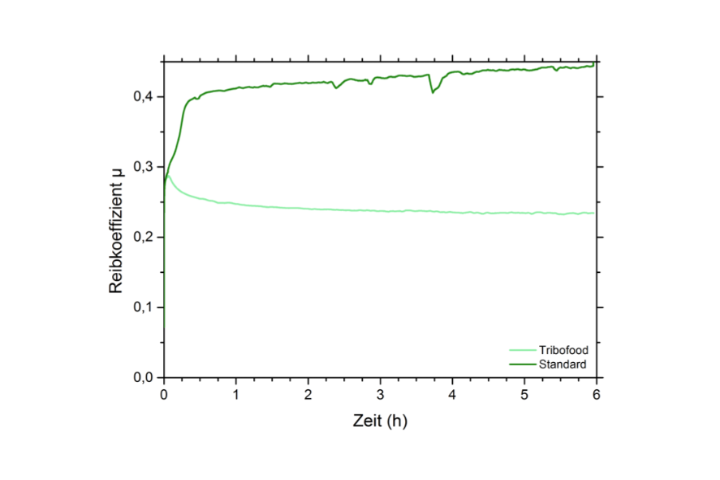

The second diagram shows the progression of friction over time. The difference between the two POM types is clear to see. Whilst with Centrodal Standard the friction value increases significa-ntly straight away and then continues to increase, Centroglide levels off and plateaus at a signifi-cantly better level.

Because it is also food-grade complaint, POM Centroglide is particularly suitable for applications in the foodstuffs industry, e.g. in the cake mix area, and in the adhesives industry.

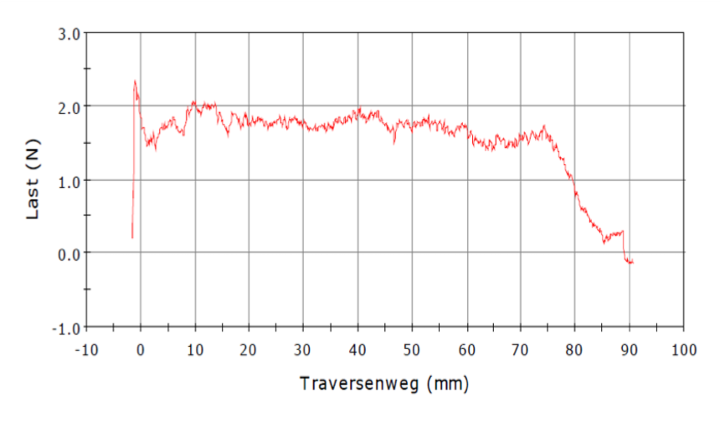

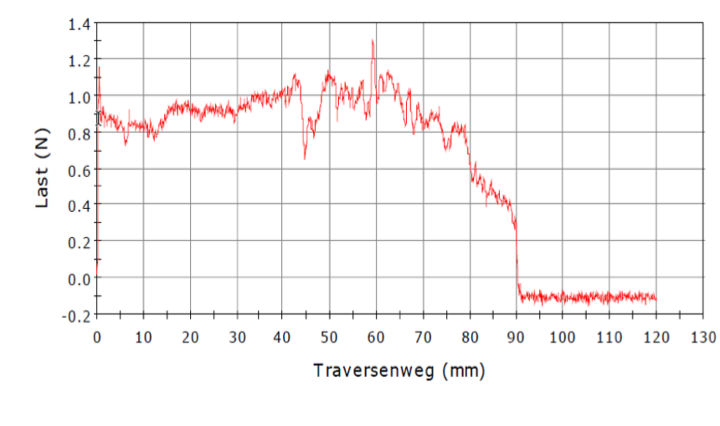

Centroglide optimises not only the friction value, but also the behaviour with sticky friction part-ners such as the aforementioned cake mix or adhesives. The other diagrams show a "90° Peel-Off" test with a known adhesive strip on Centroplast POM panels per DIN-ISO 29862:2018.

Abbildung 3. 90°-Peel-Off test on Centrodal

Abbildung 4. 90°-Peel-Off test on CentroGlide

Comparing the diagrams it is easy to see that with Centroglide the adhesive strip releases from the POM test piece with half as much load and in the same way. So, it is significantly less adhesi-ve. This distinguishes Centroglide as a low-friction material, in particular compared to Teflon.

The combination of the characteristics of POM (incl. high strength, stiffness and toughness, excellent machinability and high dimensional stability as well as excellent rebound elasticity) with the slide characteristics pre-destined Centroglide to be used as a substitute material for Teflon, which is also more expensive.